Galvanized steel pipe generally has the rational cost effective in the market. Compared with other typical steel pipe coatings, such as specialized painting and powder coating, galvanization is much more labor-intensive, resulting in a higher initial cost for contractors. Besides, due to its durability and anti-corrosive properties, galvanized steel pipe can recycled and reused, which to some degree save a lot of money during the post maintenance work.

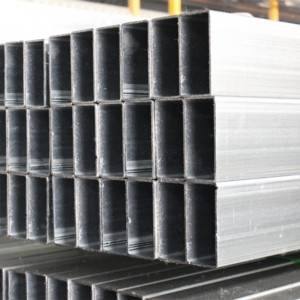

As a professional steel pipe manufacturer in China, we would like to help you make a distinction between the three major types of galvanized steel materials in a right way.

1)Hot dip galvanized steel pipe:

The hot dip galvanizing process is where an already formed part, for example plate, round, square or rectangular steel tube is dipped in a zinc bath. A reaction takes place between the steel and the zinc during the time the part is in the zinc bath. The thickness of the zinc coating is influenced by a number of factors, including the surface of the steel pipe, the time the steel pipe is dipped in the bath, the composition of the steel pipe as well as the steel pipe's size and thickness.

One advantage of hot dip galvanizing is that the entire part is covered including the edges, welds, etc. giving it an all-round corrosion protection. The end product can be used outdoors in all different weather conditions. It is the most popular galvanizing method and is widely used in the construction industry.

2)Pre-galvanized steel pipe:

Pre-galvanized steel pipe refers to steel pipe which was galvanized while in sheet format, thus prior to further manufacturing. Pre-galvanization is also known as mill galvanized, due to the fact that the steel sheet is rolled through molten zinc. After the sheet is sent through the mill to be galvanized it is cut to size and recoiled. A specific thickness is applied to the entire sheet, for example pre-galvanized Z275 steel has a 275g per square meter zinc coating. One of the advantages which pre-galvanized steel has over hot dip galvanized steel is that it has a better appearance.

pre-galvanized materials are used for a wide variety of products including conduit, lip and open channels.

3)Electro-galvanized steel pipe:

Electro-galvanized steel pipe refers to applying a zinc coat deposited onto the steel pipe using electro deposition. Electro-galvanized steel pipe has the advantage that the coating thickness can be controlled independently on the in- and outside parts. The thickness of the coating applied through electro galvanization is precise.

Send your message to us:

Post time: Apr-08-2019