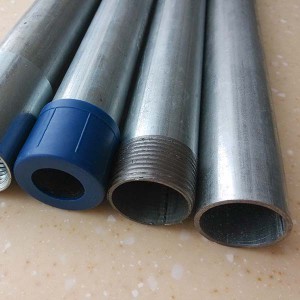

OEM/ODM Factory China 3/4 Inch BS4568 Steel Electrical Gi Conduit Pipe with Galvanized

Short Description:

Product Detail

Product Tags

Our firm promises all people from the first-class goods along with the most satisfying post-sale company. We warmly welcome our regular and new shoppers to join us for OEM/ODM Factory China 3/4 Inch BS4568 Steel Electrical Gi Conduit Pipe with Galvanized, Our corporation is dedicated to giving customers with superior and secure excellent items at competitive rate, creating just about every customer content with our services and products.

Our firm promises all people from the first-class goods along with the most satisfying post-sale company. We warmly welcome our regular and new shoppers to join us for China Pipe, Conduit Pipe, Till now, the goods list has been updated regularly and attracted clients from around the globe. In depth facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They will help you get in depth acknowledge about our goods and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any delighted co-operation.

| Product Name: | UL797 ANSI C80.3 electrical conduit |

| Material Grade | Q195,Q235 |

| Surface Finished | Pre galvanized or hot dipped galvanized |

| Standard | UL797 ANSI C80.3 |

| Length | 3.05M or customized length |

|

STANDARD EMT CONDUIT |

||||||

| Standard | Nominal Size | Outside Diameter | Wall Thickness | Length | ||

| UL 797 ANSI C 80.3 | inch | inch | mm | mm | feet | mm |

| 1/2″ | 0.706 | 17.93 | 1.07 | 10 | 3050 | |

| 3/4″ | 0.922 | 23.42 | 1.24 | 10 | 3050 | |

| 1″ | 1.163 | 29.54 | 1.45 | 10 | 3050 | |

| 1-1/4″ | 1.510 | 38.35 | 1.65 | 10 | 3050 | |

| 1-1/2″ | 1.740 | 44.20 | 1.65 | 10 | 3050 | |

| 2″ | 2.197 | 55.80 | 1.65 | 10 | 3050 | |

| 2-1/2″ | 2.875 | 73.03 | 1.83 | 10 | 3050 | |

| 3″ | 3.500 | 88.90 | 1.83 | 10 | 3050 | |

| 3-1/2″ | 4.000 | 101.60 | 2.11 | 10 | 3050 | |

| 4″ | 4.500 | 114.30 | 2.11 | 10 | 3050 | |

| MATERIAL:Q195&Q235 | ||||||

| CLASS:class 3&class 4 | ||||||

|

ECONOMIC EMT CONDUIT |

||||||

| Standard | Nominal Size | Outside Diameter | Thinner wall Thickness | Length | ||

| UL 797 ANSI C 80.3 | inch | inch | mm | mm | feet | mm |

| 1/2″ | 0.706 | 17.93 | 0.85 | 10 | 3050 | |

| 3/4″ | 0.922 | 23.42 | 1.00 | 10 | 3050 | |

| 1″ | 1.163 | 29.54 | 1.10 | 10 | 3050 | |

| 1-1/4″ | 1.510 | 38.35 | 1.30 | 10 | 3050 | |

| 1-1/2″ | 1.740 | 44.20 | 1.30 | 10 | 3050 | |

| 2″ | 2.197 | 55.80 | 1.40 | 10 | 3050 | |

| MATERIAL:Q195&Q235 | ||||||

| CLASS:class 3 | ||||||

| Applicable Tolerances: | ||||||

| Length: 10Ft (3.05m) ± ¼” (±6.35mm). | ||||||

| Outside Diameter: ½”-2” ±0.005” (±0.13mm); 2½” ±0.010” (±0.25mm); 3” ±0.015” (±0.38mm); | ||||||

| 3½”-4” ±0.020” (±0.51mm) | ||||||

Our Competitive Advantage:

1,Safe Product.

Our conduit is safe, easy to install, with wide production range, and has shielding performance,

anti-jamming performance, fire prevention and many other good performance. It is the preferred

wire pulling material of modern building.

2,Good Raw Material.

Our conduit is processed by high-quality hot dipped galvanized coil, with zinc layer thickness more

than 120G / M²,which extends the life of the conduit. Zinc coating is well-distributed, good finished

with smooth surface, without black spots and bubbles, and has strong corrosion resistance. It is

suitable for wires protect installation of lighting and machinery equipment in wet, corrosive

harsh environment. Higher-quality products can be customized according to customer’s

requirements.

3,Good Weld Line.

Weld line is smooth, and the height of inner weld line does not exceed 0.3 mm, which keep the

conduit suitable for wire pulling and no damage to the wires.

4,Clean End of the Conduit.

The end of our conduit is cut off squarely and cleaned without any burrs and sharp edges, which

will not damage the wire.

5,Perfect Inspection Process.

Our company has a perfect product inspection process to ensure that products we offer you are qualified.

6,Withstand a variety of tests.

Our products have a perfect performance in the threading test, zinc layer testing, stamping tests, bending

tests and other physical and chemical tests.